compression test concrete procedure|concrete strength chart time : ODM The testing involves applying a compressive axial load to cylindrical concrete specimens at a specified rate until the specimen fails. The compressive strength is then .

TuAzar, La revista del azar. Revisa en TuAzar.com los result.

{plog:ftitle_list}

Catholic Candles, including saint, Jesus, vigil candles, candl.

Procedure for Concrete Cube Test. Remove the specimen from the water after specified curing time and wipe out excess water from the surface. Take the dimension of the specimen to the nearest 0.2m. Clean the bearing surface of .

Learn about ASTM C39 tests in construction and testing the compressive strength of concrete cylinders and ensuring structural safety.Advancing concrete knowledge. Guide for Obtaining Cores and Interpreting Compressive Strength Results. Copyright by the American Concrete Institute, Farmington Hills, MI. All .Compressive strength is measured by breaking cylindrical concrete specimens in a compression-testing machine. Compressive strength is calculated from the failure load divided . A concrete test evaluates the compressive strength of cured concrete using the concrete cube test formula. Engineers use this test to ensure the concrete meets its anticipated compressive strength, determined through .

The testing involves applying a compressive axial load to cylindrical concrete specimens at a specified rate until the specimen fails. The compressive strength is then .Compressive strength test results are primarily used to determine that the concrete mixture as delivered meets the requirements of the specified strength, ƒ′c, in the job specification.

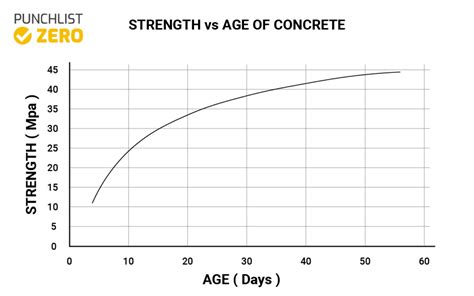

concrete strength chart time

ASTM C39 is the standard test method for compressive strength of cylindrical concrete specimens. The standard outlines procedures for subjecting cylindrical concrete specimens to axial compressive forces until failure occurs.The compressive strength test of concrete is an essential procedure that helps engineers and construction professionals evaluate the strength and durability of concrete structures. The test is commonly done on concrete cubes, using a .concrete in an existing structure can be evaluated using cores. This in-place strength determination is simplified . with standardized testing procedures. 1.3—Scope This guide summarizes current practices for obtaining cores and interpreting core compressive strength test results in light of past and current research findings. Many of these

A compression testing machine is a universal testing machine (UTM) specially configured to determine a material’s strength and deformation behavior under compressive (pressing) load. A typical machine for compression tests . Several factors can lead to equipment malfunctions, such as deviation from correct test procedures, faulty fracture patterns of the specimen, or sudden rupture due to the testing machine’s limited flexibility. . Certified . The compression testing machine is the main tool for evaluating concrete strength. It is also used for testing the compressive strength of various materials. Now, let’s explore the equipment and test methods used in compressive testing. Compression Testing Machines. Compression testing machines come in two main types: hydraulic and servo .Procedure of Flexural Test on Concrete. The test should be conducted on the specimen immediately after taken out of the curing condition so as to prevent surface drying which decline flexural strength. Place the specimen on the loading points. The hand finished surface of the specimen should not be in contact with loading points.

Compression testing is one of the most fundamental types of mechanical testing, alongside tensile and flexion tests. Compression tests are used to determine a material’s behavior under applied crushing loads, and are typically conducted by applying compressive pressure to a test specimen (usually of either a cuboid or cylindrical geometry) using platens or specialized .

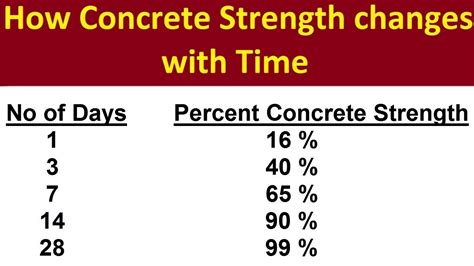

The compressive strength of M20 grade concrete varies between 17 and 23 N/mm2 (i.e. between 170 kg/cm^2 and 230 kg/cm^2) after 28 days curing. This means that the concrete can withstand a compressive load of 170 to 230 kg/cm² before it fails.. In compressive strength test of concrete cube the push force applied on the both faces of concrete specimen and the maximum .ASTM C39 has updated the test control methods when crushing concrete. The speed of your testing is dictated by the control type, and it is important to make sure you are testing quickly and efficiently. . Test Setup, Procedure, and Calculations. ASTM C39 requires that the prepared concrete sample be placed on the lower platen of a compression . The American Society for Testing and Materials (ASTM) provides standardized procedures for testing the compressive strength of concrete, ensuring consistency and reliability in the results. The procedure, as outlined in ASTM C39/C39M, involves several key steps: Sample Preparation: Concrete samples are cast in cylindrical molds and cured.x A 3 or 7-day test may help detect potential problems with concrete quality or testing procedures at the lab but is not a basis for rejecting concrete, with a requirement for 28-day or other age strength. x ACI 318, ACI 301 and ASTM C1077 requires that laboratory technicians involved in testing concrete must be certified.

Air-entrained concrete is typically specified in areas of the country where frost-related damage can occur. The measurement of air content in fresh concrete of normal density is typically performed using the pressure method ().Another useful test is ASTM C 173.However, the pressure method is frequently preferred because it is relatively fast. A low compressive strength can lead to structural failure and compromise the safety of the structure. Therefore, testing the compressive strength of concrete is essential. Also Try: Concrete Yard Calculator. Procedure of Concrete Compression Test. The procedure of conducting a concrete compression test is straightforward and involves the .

Compressive strength testing of concrete:-The test is carried out using 150mm concrete cubes on a Universal testing machine or compressive testing machine. Apparatus. As per IS: 516-1959 Compressive testing machine (2000Kn),15cm×15cm×15cm steel cube molds or Cylinder having Dia 15cm and length 30cm are used. The test includes following steps:-Procedure for rebound hammer test on concrete structure starts with calibration of the rebound hammer. For this, the rebound hammer is tested against the test anvil made of steel having Brinell hardness number of about 5000 N/mm2. . The most suitable method of obtaining the correlation between compressive strength of concrete and rebound .Sections 26.5.3.2 and 26.12.1.1 of ACI 318-19, ACI 301-20 “Specifications for Concrete Construction”, and ACI 311.6-18 “Specification for Testing Ready Mixed Concrete” require concrete strength tests for acceptance to be the average of at least two 6 x 12 in. (150 x 300 mm) cylinders or at least three 4 x 8 in. (100 x 200 mm) cylinders. The Procedure for Conducting a Concrete Cube Test. . Adherence to these preparation steps enables the assurance of quality and consistency in your concrete cube specimens. Compression Testing .

2.1 This clause specifies the procedure for making and curing compression test specimens of concrete in the laboratory where accurate control of the quantrties of matt.. rials and test conditions are possible and where the maxnnum nominal size of aR~re~atedoes not exceed 38 mm. The method IS specially applicable to the making of preliminary .

The standard test method is applicable to concrete specimens, molded cylinders, and drilled cores, specifically for those with a unit weight exceeding 50 lb/ft³ [800 kg/m³]. . The ends should be smooth and perpendicular to the specimen's axis, ensuring uniform force distribution during testing. Testing Procedure. Preparation: Prepare the .ISO 1920-10:2009 – Testing of concrete — Part 10: Determination of static modulus of elasticity in compression: This standard provides the procedure for determining the static modulus of elasticity in compression of hardened concrete on test specimens.

Following are the procedure for testing the Compressive strength of Concrete Cubes Apparatus for Concrete Cube Test. Compression testing machine. Preparation of Concrete Cube Specimen. The proportion and material for making these test specimens are from the same concrete used in the field. Specimen. 6 cubes of 15 cm size Mix. M15 or aboveASTM C39 Procedure. 1. Bring the cylinders out of the moisture room, keeping them covered with wet burlap to keep them moist. Check the cylinders over for defects (holes, cracks, crumbliness) as you set them on the table, use your straight edge and nail to check for planeness, and set the ones with ends that are not plane aside to be saw cut.

🕑 Reading time: 1 minute Compressive strength of concrete Blocks or concrete masonry units are required to know the suitability of these in construction works for various purposes.

The Procedure for Testing Concrete Cube Compressive Strength. Performing a test for the compressive strength of a concrete cube consists of a few steps. First off, the concrete being tested is poured into a mould meeting the size requirements mentioned above — 150 x 150 x 150mm. Second, the concrete is appropriately tempered to remove any .

The testing of concrete cores is carried out according to the ASTM Standard C 42. Core sampling and procedure for strength determination using concrete core is discussed. . the test specimens in lime-saturated water at 23.0 +/- 1.7° C for at least 40 h immediately prior to making the compression test. Test the specimens promptly after .For that matter, A certain quantity of concrete shall be cast as a cube while concrete pouring time to find the compressive strength of that concrete batch. The cube will be preserved and curated well for almost 28 days to be tested by the Compression Testing Machine. Compressive Strength of Concrete TestConcrete cylinder samples; Compression testing machine or UTM Machine; Scale; Tamping rod; Moulds; Water; Curing tank; Theory. . Test Procedure. Sample Preparation. Use cylindrical molds to create concrete samples of standard dimensions .Sampling of Materials for Slump Test A concrete mix (M15 or other) by weight with suitable water/ cement ratio is prepaid in the laboratory similar to that explained in 5.9 and required for casting 6 cubes after conducting Slump test. Figure-1: Measuring Slump of Concrete. Procedure for Concrete Slump Cone Test

concrete strength after 3 days

Umidade Quantidade De Umidade Presente No AR Em Rela.

compression test concrete procedure|concrete strength chart time